— Knowledge —

— PRODUCTS —

Service Hotline +8613974960765

Service Hotline +8613974960765 Email:susie@hnljpump.com

Mobile:+8618507312158

TEL:+8613974960765

vertical turbine pump

发布时间:2024/1/5 22:30:53 人气: [content:visits]

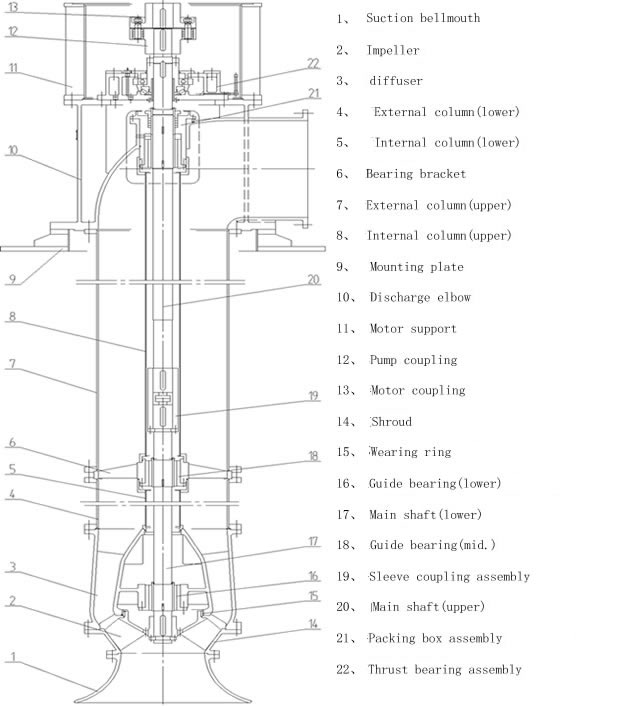

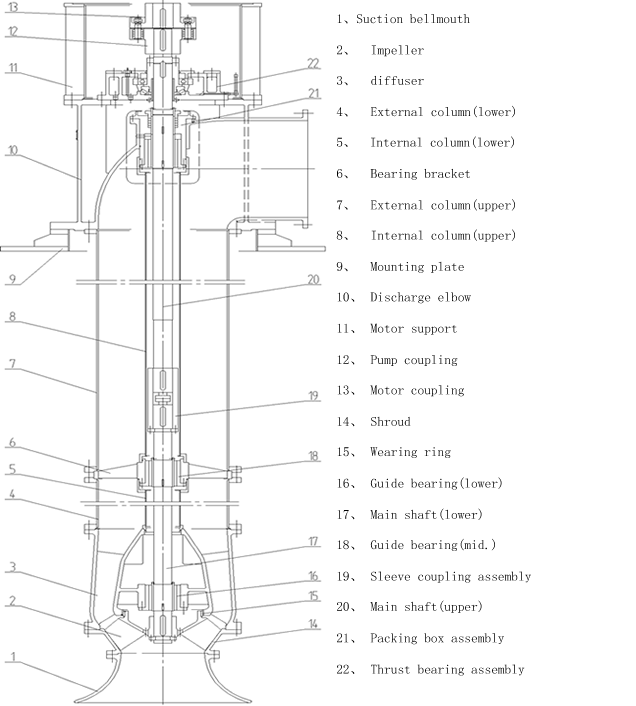

Structure feature of The LK ,LB Vertical axial-(mixed)-flow turbine pumps

Structure feature:

1. Series LK ,LB Vertical axial-(mixed)-flow turbine pumps are of vertical single stage and/or multistage centrifugal or mixed flow with diffuser types.

2. The following structure types are available for the turbine pump:the discharge opening above and/or under the mounting foundation(Type Code named S and X respectively);the axial thrust force born by the turbine pump and/or by the motor(Type Code named T and D);lubricating water from outside and/or from the turbine pump itself.

3. The intake sump is of wet pit and/or dry pit types.

Wet pit type:lower part of the turbine pump inundated in the intake sump.

Dry pit type:the water enters into the turbine pump,the suction bellmouth is connected with the inlet pipe of the turbine pump by means of elbow bend pipe of 90。.

4. Rubber guide bearings and /or the Thordon guide bearings are available for bearings of the turbine pump.

5. Generally when the nozzle diameter of the turbine pump is under 1000mm , non pull-out type is adopted for the rotor and the discharge opening is above the mounting foundation(Type Code named ST). In this case the axial thrust force and the weight of the rotor are usually born by thrust bearings of the turbine pump itself and flexible connection is adopted between the turbine pump and the motor.The thrust force and the weight of the rotor can also be born by the motor if required,or other structure types such as SD,XT,XD are available .Rotor pull-out type can also be adopted if required by clients.

Generally when the discharge diameter of the turbine pump is above 1000mm, pull-out type is adopted for the rotor and the discharge opening is under the mounting foundation(Type Code named XD).In this case the axial thrust force and the weight of the rotor are usually born by thrust bearings of the motor and rigid connection is adopted between the turbine pump

and the motor. The axial thrust force and the weight of the rotor can also be born by

the turbine pump if required,or other structure types such as XT,SD,ST are available .Rotor non pull-out type can also be adopted if required by clients.

6. When the axial thrust force and the weight of the rotor are born by turbine pump itself,the thrust bearing of the turbine pump is lubricated with dilute oil and is equipped with a temperature detector Pt100 to detect bearing temperature and a pressure type thermometer to detect the temperature of lubricating oil.

7. The antielectrochemical corrosion appliance is adopted for the part of the turbine pump contacting the liquid to ensure the service life of the turbine pump when seawater is turbine pumped.

8. The packing seal is adopted for the axial seal of the turbine pump.

9. The clearance between the impeller and the impeller chamber,i.e.the rotating component and the static component,can be easily adjusted on the turbine pump mounting foundation.

10. The motor terminal box and turbine pump external lubricating water pipe are lied on left when viewed from outlet to turbine pump. It also can installed in any other direction base on guest of demand.

China vertical turbine pump manufacturer provides various stainless steel and duplex steel vertical turbine pumps with affordable prices and stable performance. For more information, please contact 008613974960765.

Previous:the structure of Vertical axial-(mixed)-flow turbine pumps

Next:Structural Features OF VS1/VS6 series vertical suspended turbine pumps

相关推荐

screenshots ,WeChat Scan the Qr Code

WeChat:ljpump6666