— Knowledge —

— PRODUCTS —

Service Hotline +8613974960765

Service Hotline +8613974960765 Email:susie@hnljpump.com

Mobile:+8618507312158

TEL:+8613974960765

vertical turbine pump

发布时间:2024/10/22 0:34:47 人气: [content:visits]

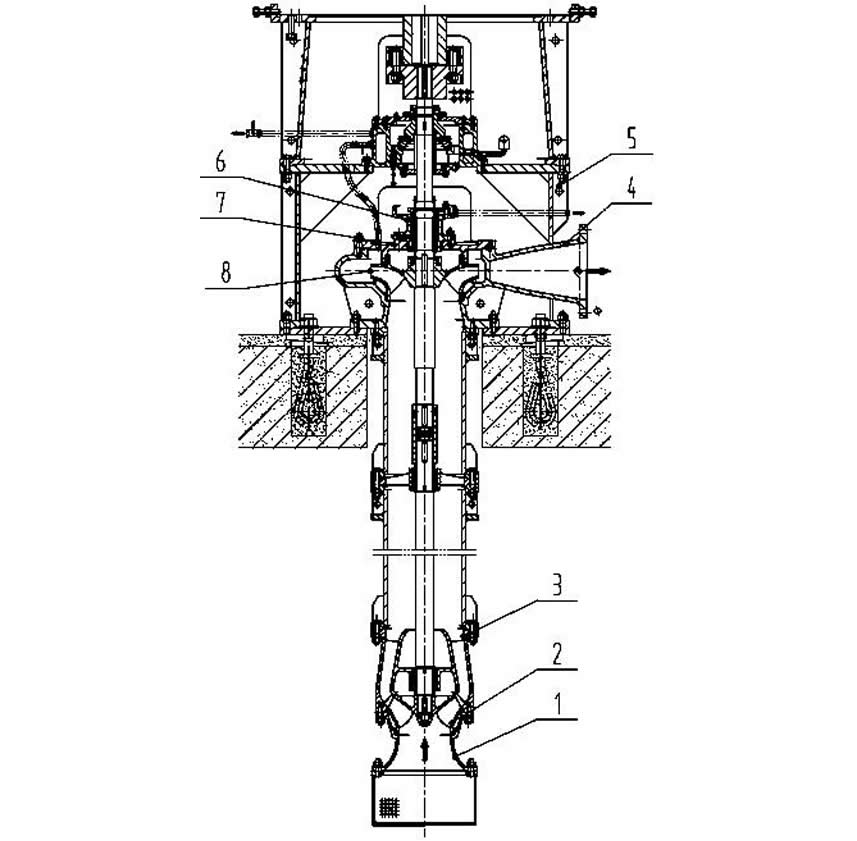

Double wheel snail shell suspended semi submersible vertical turbine pump

Double wheel snail shell suspended semi submersible vertical turbine pump, including suction horn mouth, first stage impeller, guide vane body, snail shell pump body, thrust bearing seat, packing sealing component, pump cover, and secondary impeller. The first stage impeller is below the liquid level, the secondary impeller is above the foundation layer, the volute pump body is at the center of the thrust bearing seat, and the packing sealing component is installed on the pump cover. When the pump is running, the liquid is transported to the secondary impeller and volute pump body above the foundation layer and below the liquid level through hydraulic components such as the first stage impeller and guide vane body, and then discharged outside the pump. This technical method has stable performance, simple structure, and easy installation; There are few underwater parts, small radial force, easy installation and maintenance, and stable operation; The snail shell outlet channel can balance radial forces; Under high head and high flow conditions, the efficiency of the snail shell flow channel is 5% to 8% higher than that of traditional flow channels.

Technical requirements: 1. A double wheel snail shell suspended semi submersible vertical turbine pump, characterized in that it comprises a suction horn mouth (1), a first stage impeller (2), a guide vane body (3), a snail shell pump body (4), a thrust bearing seat (5), a packing sealing component (6), a pump cover (7), and a secondary impeller (8). The suction horn mouth (1), the first stage impeller (2), and the guide vane body (3) are located below the foundation layer and the liquid level. The secondary impeller (8) and the snail shell pump body (4) form an outlet channel above the foundation layer. The snail shell pump body (4) is installed at the center of the thrust bearing seat (5), and the packing sealing component (6) is installed. On the pump cover (7), an axial sealing system is formed.

相关推荐

screenshots ,WeChat Scan the Qr Code

WeChat:ljpump6666